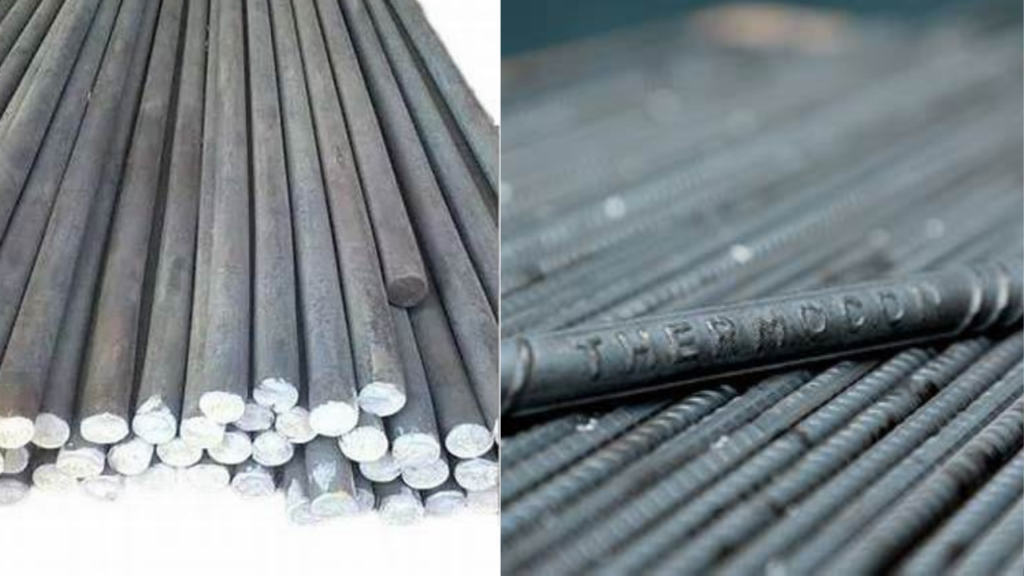

In the world of construction, choosing the right type of reinforcement material can make all the difference between a strong, long-lasting structure and one that’s vulnerable to damage or failure.

Two common types of steel used in construction in Nigeria are Mild Steel and TMT (Thermo-Mechanically Treated) Bars.

While both serve the purpose of reinforcing concrete, they are very different in terms of strength, durability, and performance.

Understanding the difference between mild steel and TMT bars is essential for builders, engineers, and anyone involved in construction projects.

Table of Contents

ToggleSee also – What are the different types of iron rods used in construction?

1. Composition and Manufacturing Process

Mild Steel Bars:

- Made from low-carbon steel (typically around 0.15–0.25% carbon).

- Manufactured through a rolling process without any heat treatment.

- Surface is smooth and plain, with no ridges.

TMT Bars:

- Also made from steel, but processed through a thermo-mechanical treatment.

- This involves quenching (rapid cooling), self-tempering, and atmospheric cooling to form a hard outer surface and soft inner core.

- Surface is ribbed for better bonding with concrete.

2. Strength and Load-Bearing Capacity

Mild Steel:

- Has lower tensile strength (around 250 N/mm²).

- Not suitable for high-load or large structures.

TMT Bars:

- Available in higher grades like Fe-415, Fe-500, Fe-550, and Fe-600.

- Tensile strength starts at 415 N/mm², making them ideal for heavy-load construction.

See also – How can you tell good quality TMT bars?

3. Flexibility and Ductility

Mild Steel:

- Highly ductile and easy to bend without breaking.

- Often used where flexibility is more important than strength.

TMT Bars:

- Also ductile (especially in lower grades like Fe-415).

- However, offer better balance between flexibility and strength, making them safer during earthquakes and heavy winds.

4. Bonding with Concrete

Mild Steel:

- Smooth surface results in weaker bonding with concrete.

- Often needs additional binding agents or mechanical anchorage.

TMT Bars:

- Ribbed surface ensures strong grip with concrete, reducing the chances of slippage and structural failure.

5. Corrosion Resistance

Mild Steel:

- Highly prone to rust when exposed to moisture.

- Requires extra coatings or anti-rust treatment.

TMT Bars:

- The quenching process forms a protective outer layer.

- Offers much higher corrosion resistance, making them ideal for coastal and damp environments.

6. Earthquake and Fire Resistance

Mild Steel:

- Poor resistance to high temperatures and seismic stress.

TMT Bars:

- Excellent performance in earthquake-prone zones due to superior ductility.

- Can withstand high temperatures up to 600°C, offering better fire resistance.

See also – What are the grades of TMT steel rods?

7. Cost

Mild Steel:

- Generally cheaper upfront, but may lead to higher maintenance and repair costs in the long run.

TMT Bars:

- Slightly more expensive, but offer long-term savings through better durability and performance.

Which One Should You Use?

- For small-scale fencing use Mild Steel

- For residential buildings use TMT Bars (Fe-415 or Fe-500)

- For high-rise and commercial structures use TMT Bars (Fe-500 or higher)

- In coastal or damp areas use TMT Bars

- In earthquake-prone zones TMT Bars

Conclusion

While mild steel has its place in small-scale or temporary construction, TMT bars are the superior choice for modern building projects that require strength, safety, and longevity.

Whether you’re building a home, office, or industrial complex in Nigeria, investing in TMT bars will give you greater peace of mind and a stronger structure.

Frequently asked questions

What is the main difference between mild steel and TMT bars?

Mild steel bars have a smooth surface and lower strength, while TMT bars undergo a thermo-mechanical treatment process, making them stronger and more durable.

Which is better for construction: mild steel or TMT bars?

TMT bars are preferred for construction due to their higher tensile strength, ductility, and corrosion resistance, making them ideal for load-bearing structures.

Why do TMT bars have ribs while mild steel bars are smooth?

The ribs on TMT bars improve their bonding with concrete, enhancing structural integrity, whereas mild steel bars are smooth and require additional anchoring.

Are mild steel bars weaker than TMT bars?

Yes, mild steel bars have lower tensile strength and are more prone to bending, while TMT bars are designed to withstand heavy loads and seismic forces.

Which type of steel is more resistant to corrosion?

TMT bars have better corrosion resistance due to their manufacturing process, while mild steel bars require protective coatings to prevent rust.